10 Reasons Why These Texas-Made Tactical Pants Are The Best Work Pants For Tradesmen In 2026

By Marcus T.

"Read this BEFORE you waste another $40 on jeans that blow out in 8 weeks!"

TL;DR: Switching to Black Buck Pants has 10+ game-changing benefits for tradesmen 👇

1. NEW Triple Armor Construction that eliminates the blow-out cycle

Black Buck cracked the code to work pants that actually survive jobsite abuse. The game-changing combo of double-layered knee reinforcement, diamond gusset construction, and nearly 2-pound fabric weight is a life-hack when it comes to ending the constant replacement cycle. All while still getting the freedom of movement you need.

You can kneel on concrete, squat in crawl spaces, and climb ladders without that split-second panic of "did my pants just rip?"

The three engineering features work together: extra fabric panels at the exact spots where your knees destroy regular jeans (those tan base with black knee panels aren't just style), a diamond-shaped gusset that allows full range of motion without seam stress, and fabric so thick you can feel the difference the moment you put them on. Ditching cheap Walmart jeans has never been easier.

2. Try-Before-You-Pay completely removes the purchase risk

Black Buck's Try-Before-You-Pay model solves the #1 reason guys avoid buying work pants online: "What if they don't fit and I'm stuck dealing with returns?"

Here's how it works: You order your size today. Black Buck ships them to your door with free shipping. Your card is NOT charged. For the next 10 days, you try them on at home, wear them on actual jobsites, kneel on concrete, squat under sinks, climb ladders – test them in real work conditions. If they don't fit perfectly or don't perform like they promised, you email customer service before the 10 days are up and they simply cancel your payment. No return shipping. No refund hassle. You just don't get charged.

Only pay if they earn it.

3. Nearly 2-pound fabric weight makes them last 10X longer

Most tactical pants weigh 6-7 ounces per pair. Black Buck Pants weigh nearly 2 POUNDS. That's not a typo.

When you pick them up, you immediately feel the difference. The 65% polyester and 35% cotton blend is woven so thick that the fabric alone weighs more than some entire pairs of competitor pants. That extra weight translates directly to durability. Thicker fabric = tighter weave = more resistance to abrasion when you're kneeling on gravel, crawling in attics, or sliding across truck beds.

The polyester gives you stain resistance (because let's be real, tradesmen get dirty). The cotton keeps them breathable so you're not dying in summer heat. Black Buck customers report wearing the same pair for 6+ months of daily jobsite abuse without blown-out knees or split crotches.

4. Made in Texas, USA – not rushed through an overseas factory

Every single pair of Black Buck Pants is cut, sewn, and inspected in Texas by American workers earning American wages.

This isn't "designed in America, assembled overseas" nonsense. This isn't "final assembly in the USA with imported materials." These are fully American-made from start to finish – from fabric sourcing to the final stitch.

Why does this matter? Because when something's made in Texas, the people making it understand what work pants need to be. They know what it's like to kneel on concrete for hours. They know the consequences of weak stitching at stress points. Plus, you're supporting American manufacturing jobs instead of lining the pockets of companies that chase the cheapest labor overseas.

5. Saves $240-360 annually by ending the replacement cycle

Let's do the math that most guys never sit down to calculate:

The average tradesman goes through 6-9 pairs of jeans per year because they blow out at the knees and crotch. At $40 per pair, that's $240-360 spent annually just to keep pants in your closet. Over 5 years? You're spending $1,200-$1,800 on jeans that keep failing.

Now consider Black Buck Pants: $90 once for pants that last 1-2+ years of heavy use. You're saving $150-270 in year one alone. And it's not just the pants – think about the time you're NOT wasting on shopping trips. If you bill $75/hour on side jobs, every shopping trip you avoid saves you $150-225 in lost income opportunity.

The math isn't even close. Black Buck costs more upfront but bleeds less money long-term.

6. Professional appearance that earns customer trust and more referrals

Here's what nobody talks about: your gear affects how much work you get.

When you show up to a customer's house in jeans with holes at the knees, dirt stains that won't come out, and frayed cuffs dragging on the ground, that homeowner is making a judgment call. "Is this the guy I'm trusting with my electrical work?"

Black Buck Pants solve this problem completely. The reinforced construction means no blown-out knees even after months of use. The stain-resistant polyester blend keeps them looking cleaner longer. The fit is designed for movement without looking sloppy. You show up looking like you mean business. Customers notice. More referrals follow.

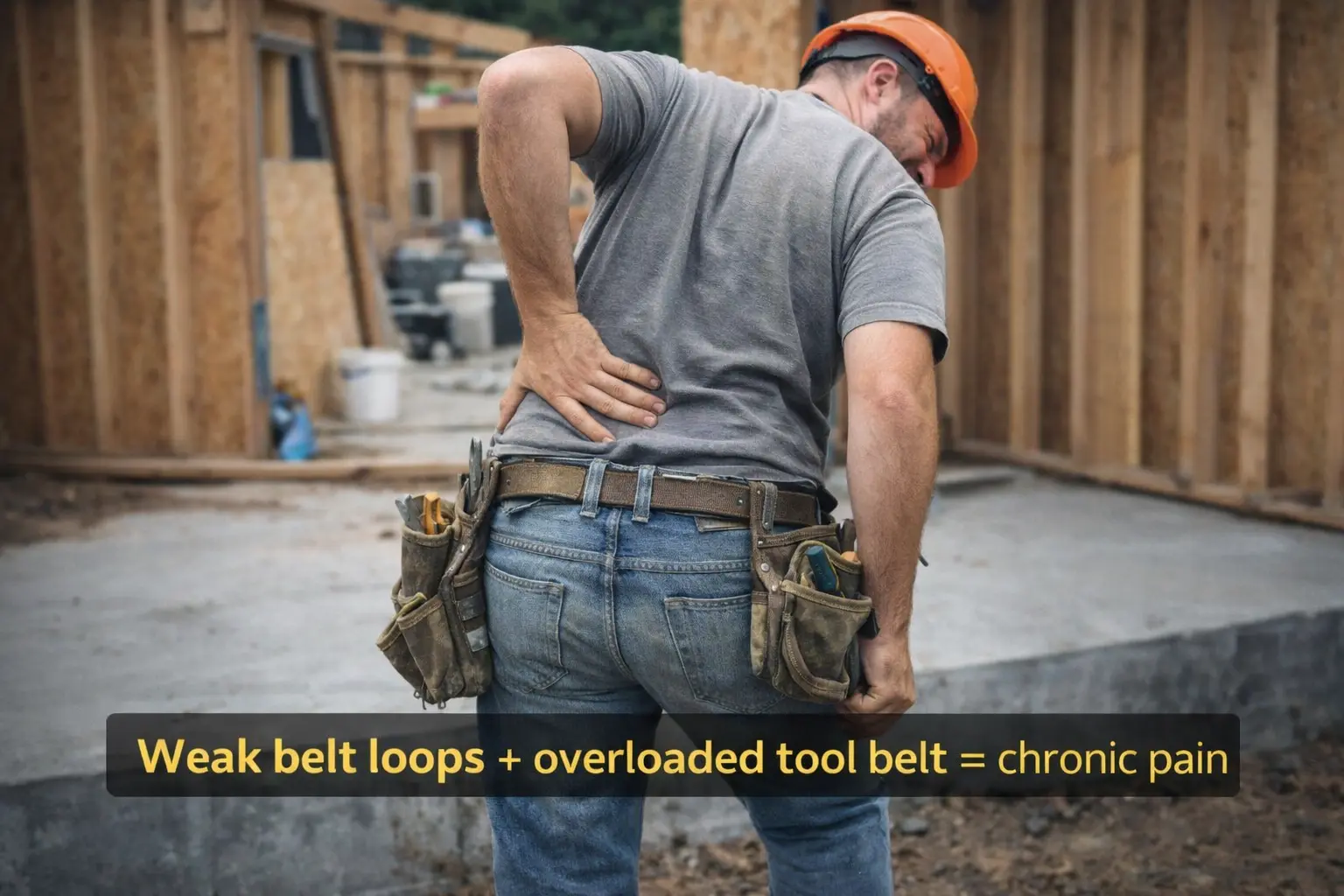

7. Reduces chronic back, knee, and hip pain from better construction

Cheap pants don't just fail faster – they hurt your body over time.

Regular jeans with thin belt loops and no reinforcement force you to carry all your tools on one belt. That's 15-20 pounds of tools pulling on your hips and lower back. By Thursday afternoon, you're in pain. By Friday, you're popping ibuprofen just to get through the day.

Black Buck Pants are engineered to protect your body: reinforced belt loops handle heavy tool belts without sagging or pulling, diamond gusseted crotch allows natural squatting without binding, proper fit means no weird twisting, and thick fabric at knees provides cushioning when kneeling on concrete.

Your work pants should help you do your job, not make it harder.

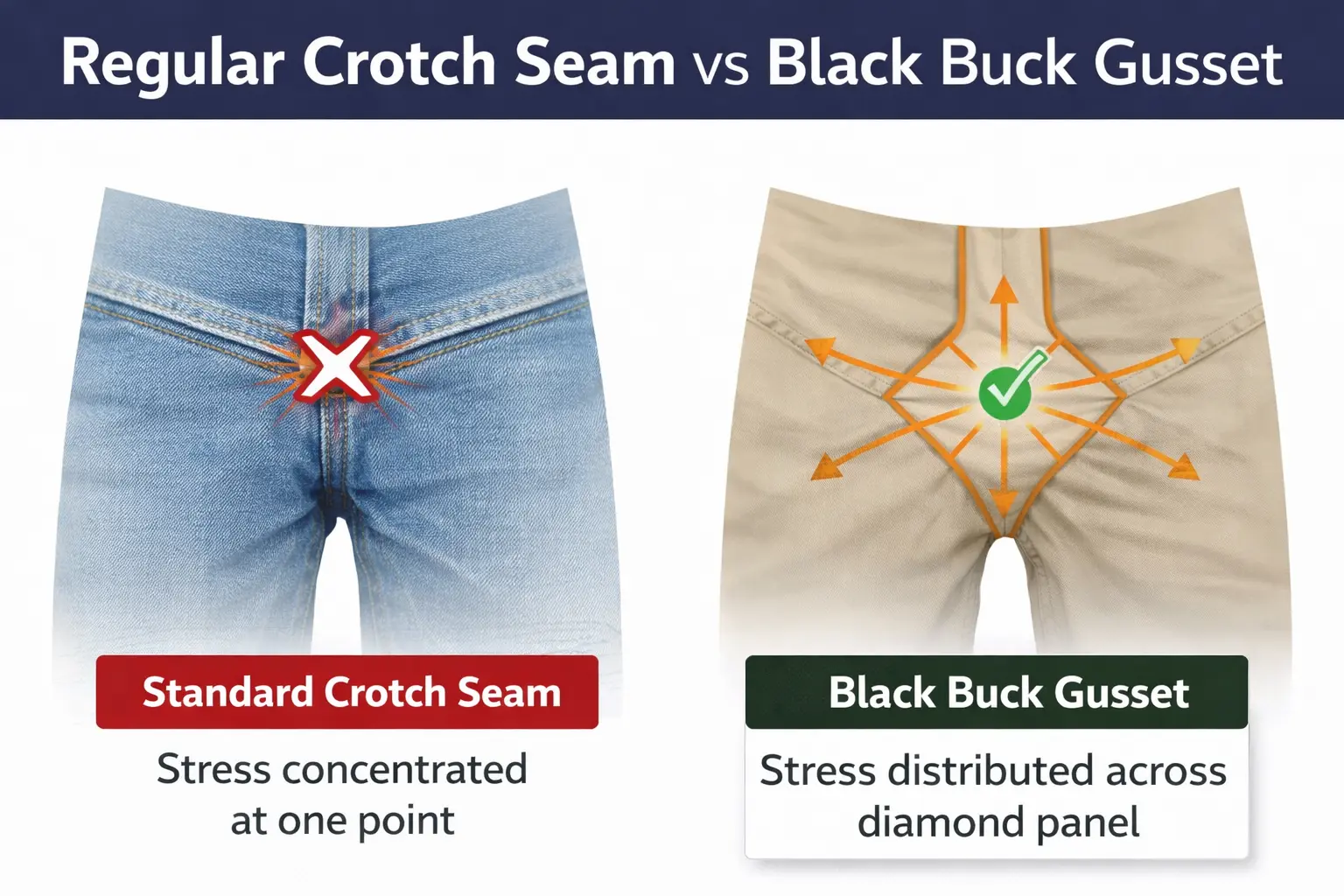

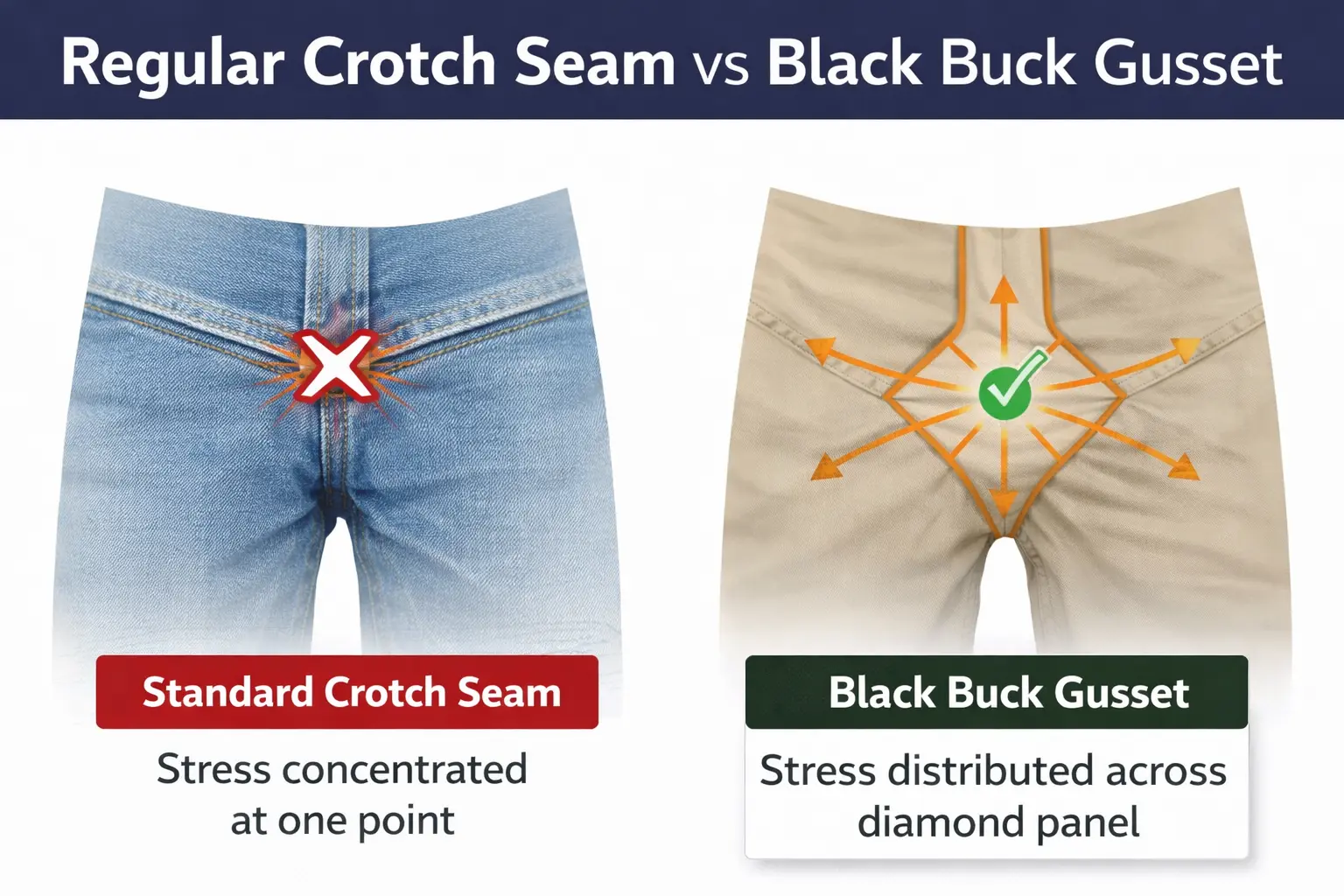

8. Gusseted crotch design prevents the #2 failure point when squatting

Everyone focuses on blown-out knees because that's the most visible failure. But ask any tradesman and they'll tell you the second most common failure point is the crotch.

You're squatting to reach a shutoff valve under a sink. You feel the fabric bind… and then you hear the split. Now you're at a customer's house with a crotch blowout trying to finish the job.

Black Buck's diamond gusset construction completely eliminates this problem. A diamond-shaped fabric panel is inserted at the crotch intersection, which distributes stress across multiple seams instead of one weak point. This allows full range of motion – you can squat deep, lunge to reach behind toilets, climb ladder rungs – without putting catastrophic stress on any single seam.

9. 4.9/5 stars from actual working tradesmen plus 10-day satisfaction guarantee

Black Buck Pants have a 4.9 out of 5-star rating from verified tradesmen purchases – not from influencers or paid models, but from electricians, plumbers, HVAC techs, welders, and contractors who wear these pants in real work conditions.

And remember: your purchase comes with the Try-Before-You-Pay guarantee. Your card isn't charged until 10 days after delivery. If they don't fit, don't perform, or you're not satisfied, simply email customer service within 10 days and they'll cancel your payment.

10. Join thousands of tradesmen who stopped the replacement cycle

In just seconds you can end the constant frustration of blown-out work pants without gambling on sizing or quality.

Thousands of electricians, plumbers, HVAC techs, contractors, and welders have already made the switch to Black Buck Pants. They're not going back to the cycle of buying $40 Walmart jeans every 8 weeks.

They found pants that actually work: double-layered reinforcement at stress points, 2-pound fabric that survives jobsite abuse, American manufacturing they can trust, and a Try-Before-You-Pay model that removes all purchase anxiety.

From fitness-focused tradesmen who need mobility, to veteran contractors who remember when work pants were built to last, to young guys just starting their careers who don't want to waste money – people just like you have discovered how to work confidently without babying their gear. You can too.